Decoding The Degree Of Polymerization: A Comprehensive Guide

Have you ever wondered what gives polymers their remarkable properties and versatility? Well, one of the fundamental concepts that unlocks the secrets behind polymers is the degree of polymerization. This crucial parameter determines the size of polymer molecules, influencing their physical and chemical characteristics. Understanding what is the degree of polymerization is essential for scientists, engineers, and anyone intrigued by the fascinating world of polymers.

The degree of polymerization is a measure of the number of monomeric units in a polymer chain. It plays a pivotal role in determining the polymer's molecular weight, which in turn affects its strength, elasticity, and thermal stability. By exploring the degree of polymerization, we can gain insights into the behavior of natural and synthetic polymers, enabling advancements in fields ranging from material science to biomedical engineering.

In this article, we'll delve into the intricate details of what is the degree of polymerization, examining its significance, how it's determined, and its impact on polymer properties. Whether you're a student, a professional, or simply curious about polymer chemistry, this guide will provide you with a thorough understanding of this key concept. So, let's dive into the world of polymers and unravel the mysteries behind their degree of polymerization.

Read also:The Ultimate Guide To The Kardashian Dating Tree Love Relationships And Connections

Table of Contents

- What is Polymerization?

- Why is the Degree of Polymerization Important?

- How is the Degree of Polymerization Determined?

- What Factors Affect the Degree of Polymerization?

- Degree of Polymerization and Molecular Weight: What’s the Connection?

- How Does Degree of Polymerization Impact Physical Properties?

- Applications of Degree of Polymerization in Industry

- Natural vs Synthetic Polymers: Differences in Degree of Polymerization

- Techniques for Measuring Degree of Polymerization

- Role of Degree of Polymerization in Biodegradable Polymers

- Recent Advancements in Polymer Research Related to Degree of Polymerization

- Common Misconceptions About Degree of Polymerization

- Frequently Asked Questions

- Conclusion

What is Polymerization?

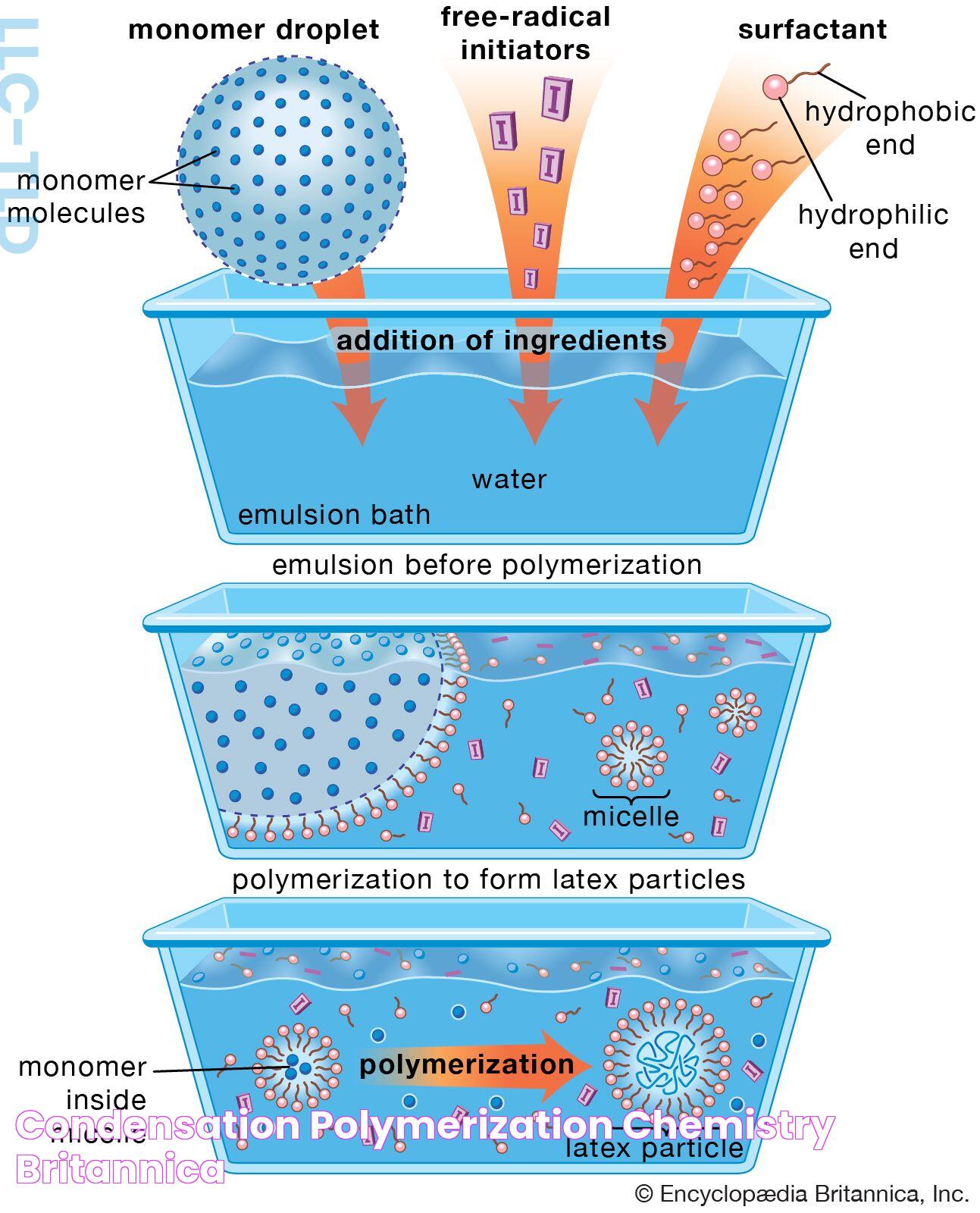

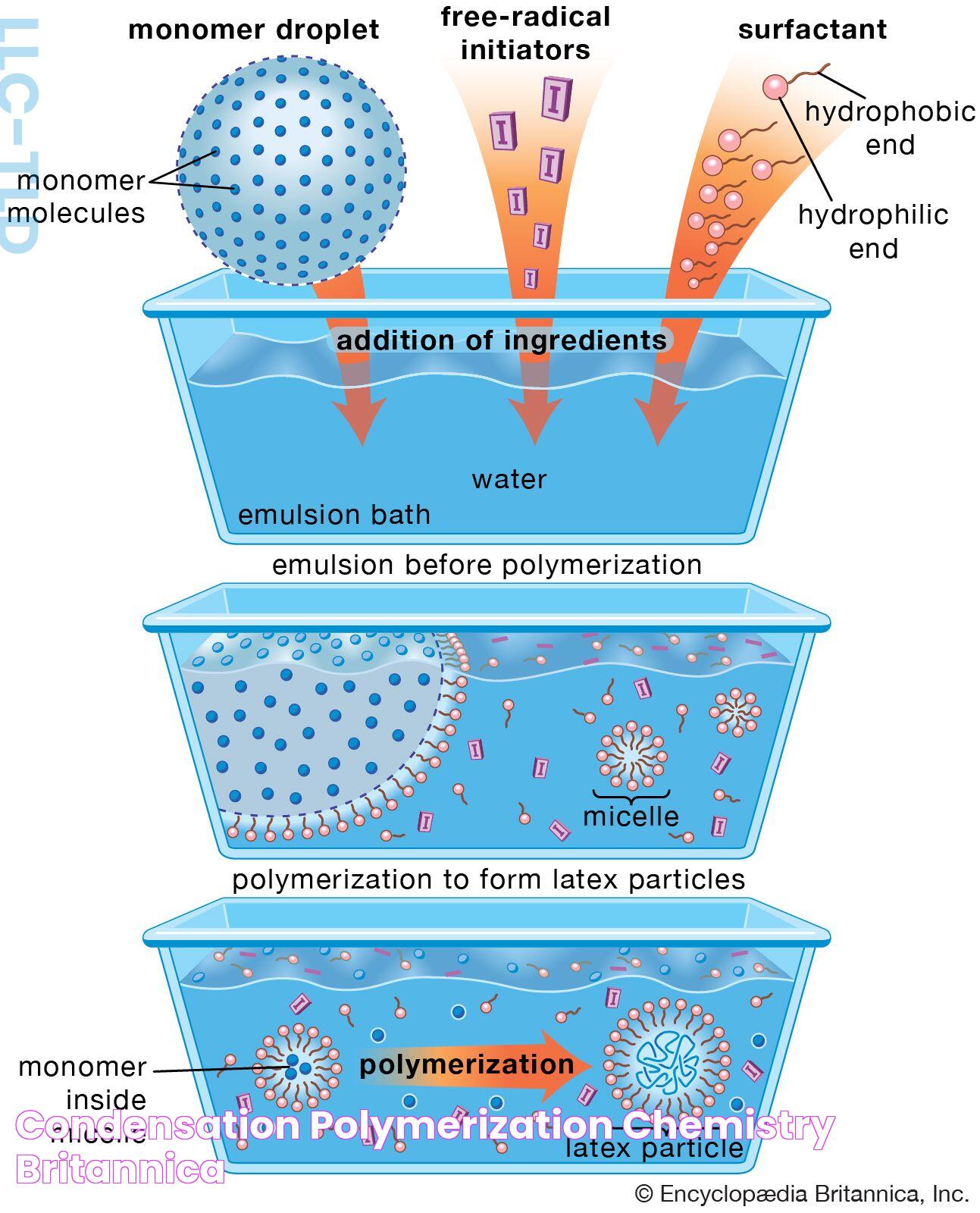

Polymerization is a chemical process that combines small molecules, known as monomers, to form a larger, repeating structure called a polymer. The process can occur through various mechanisms, such as addition polymerization or condensation polymerization, each resulting in different types of polymers with unique properties. Understanding the basics of polymerization is crucial for grasping the concept of the degree of polymerization, as it directly relates to the number of monomer units in the final polymer chain.

Types of Polymerization Processes

- Addition Polymerization: This process involves the joining of monomers with unsaturated bonds, such as alkenes, without the loss of any small molecules. It is commonly used in the production of plastics like polyethylene.

- Condensation Polymerization: In this process, monomers with two different functional groups react to form a polymer, with the simultaneous elimination of a small molecule, such as water. This method is typical for producing polymers like nylon and polyester.

Why is the Degree of Polymerization Important?

The degree of polymerization is a critical parameter that influences the properties and performance of polymers. By determining the number of monomer units in a polymer chain, it directly affects the molecular weight and, consequently, the physical and chemical characteristics of the material. This makes it a vital factor in the design and application of polymer-based products.

Significance in Material Properties

- Mechanical Strength: Higher degrees of polymerization typically result in stronger and more durable materials, as longer polymer chains provide greater intermolecular interactions.

- Thermal Stability: Polymers with higher degrees of polymerization generally exhibit improved thermal resistance, making them suitable for high-temperature applications.

- Solubility: The degree of polymerization can also impact a polymer's solubility, with longer chains often leading to reduced solubility in solvents.

How is the Degree of Polymerization Determined?

Determining the degree of polymerization involves measuring the average number of monomer units in a polymer chain. Several methods can be employed to obtain this information, each with its advantages and limitations. Understanding these techniques is essential for accurately characterizing polymers and optimizing their properties for specific applications.

Common Measurement Techniques

- Viscometry: This method estimates the degree of polymerization by measuring the viscosity of a polymer solution and relating it to molecular weight through empirical equations.

- Gel Permeation Chromatography (GPC): GPC is a powerful technique that separates polymer chains based on their size, allowing for the determination of molecular weight distribution and average degree of polymerization.

- Nuclear Magnetic Resonance (NMR) Spectroscopy: NMR provides detailed information about the chemical structure of polymers, including the degree of polymerization, by analyzing the magnetic properties of atomic nuclei.

What Factors Affect the Degree of Polymerization?

Several factors can influence the degree of polymerization, affecting the resulting polymer's properties and performance. By understanding these factors, researchers and engineers can tailor polymer synthesis processes to achieve desired characteristics and optimize material performance for specific applications.

Key Influencing Factors

- Monomer Concentration: Higher concentrations of monomers can lead to increased degrees of polymerization by promoting more frequent chain growth reactions.

- Reaction Temperature: Temperature can significantly impact the rate of polymerization and the resulting degree of polymerization, with higher temperatures often leading to increased chain growth.

- Catalyst Presence: Catalysts can accelerate the polymerization process, enhancing the degree of polymerization and influencing the polymer's molecular weight distribution.

Degree of Polymerization and Molecular Weight: What’s the Connection?

The degree of polymerization is closely linked to the molecular weight of a polymer, as it directly determines the number of monomer units in a polymer chain. This relationship is crucial for understanding the properties and behavior of polymers, as molecular weight significantly influences mechanical, thermal, and chemical characteristics.

Understanding the Relationship

- Molecular Weight Calculation: The molecular weight of a polymer can be calculated by multiplying the degree of polymerization by the molecular weight of the repeating monomer unit.

- Impact on Properties: Higher molecular weights, resulting from increased degrees of polymerization, typically lead to enhanced mechanical strength, thermal stability, and resistance to chemical degradation.

How Does Degree of Polymerization Impact Physical Properties?

The degree of polymerization plays a vital role in determining the physical properties of polymers, significantly influencing their mechanical, thermal, and chemical characteristics. By understanding these effects, researchers and engineers can design and optimize polymer materials for a wide range of applications, from packaging to electronics.

Read also:Gary Watson Garden Gner Your Guide To A Flourishing Landscape

Key Physical Property Influences

- Elasticity: Longer polymer chains, resulting from higher degrees of polymerization, typically exhibit greater elasticity, making them suitable for applications requiring flexibility.

- Hardness: Increased degree of polymerization can lead to harder materials, as the longer chains provide more intermolecular interactions and cross-linking opportunities.

- Thermal Expansion: Polymers with higher degrees of polymerization often exhibit lower thermal expansion coefficients, making them suitable for applications requiring dimensional stability under temperature fluctuations.

Applications of Degree of Polymerization in Industry

The degree of polymerization plays a crucial role in various industrial applications, influencing the design, performance, and optimization of polymer-based materials. By understanding its impact, industries can develop innovative products and processes, enhancing efficiency and sustainability across multiple sectors.

Key Industrial Applications

- Packaging: The degree of polymerization affects the strength, flexibility, and barrier properties of packaging materials, influencing their suitability for different applications, from food to pharmaceuticals.

- Construction: Polymers with specific degrees of polymerization are used in construction materials, such as insulation and coatings, to enhance durability, thermal resistance, and weatherproofing.

- Automotive: The degree of polymerization influences the performance of polymers used in automotive components, such as tires, hoses, and interior materials, impacting their strength, flexibility, and resistance to wear.

Natural vs Synthetic Polymers: Differences in Degree of Polymerization

The degree of polymerization varies significantly between natural and synthetic polymers, affecting their properties and applications. Understanding these differences is essential for selecting the appropriate type of polymer for specific uses and optimizing material performance.

Comparative Analysis

- Natural Polymers: These biopolymers, such as cellulose and proteins, often have lower degrees of polymerization compared to synthetic polymers, resulting in unique properties, such as biodegradability and biocompatibility.

- Synthetic Polymers: Manufactured through controlled chemical processes, synthetic polymers can achieve higher degrees of polymerization, providing enhanced mechanical strength, thermal stability, and chemical resistance.

Techniques for Measuring Degree of Polymerization

Accurately measuring the degree of polymerization is essential for characterizing polymers and optimizing their properties for various applications. Several techniques are available for this purpose, each offering unique advantages and limitations.

Popular Measurement Methods

- Size Exclusion Chromatography (SEC): This technique separates polymers based on their size, allowing for the determination of molecular weight distribution and degree of polymerization.

- Light Scattering: By analyzing the scattering of light by polymer solutions, this method can provide information about molecular weight and degree of polymerization.

- End-Group Analysis: This technique involves analyzing the chemical structure of polymer end groups to determine the degree of polymerization.

Role of Degree of Polymerization in Biodegradable Polymers

The degree of polymerization plays a crucial role in determining the properties and performance of biodegradable polymers, influencing their degradation rate, mechanical strength, and environmental impact. Understanding these effects is essential for developing sustainable materials for various applications.

Impact on Biodegradable Polymer Properties

- Degradation Rate: Polymers with lower degrees of polymerization tend to degrade more rapidly, making them suitable for applications requiring quick environmental breakdown, such as packaging and agricultural films.

- Mechanical Properties: The degree of polymerization affects the mechanical strength and flexibility of biodegradable polymers, influencing their suitability for various uses, from medical implants to disposable products.

Recent Advancements in Polymer Research Related to Degree of Polymerization

Recent advancements in polymer research have led to significant developments in the understanding and manipulation of the degree of polymerization, enabling the creation of innovative materials with enhanced properties and performance. These breakthroughs are driving progress across various industries, from healthcare to electronics.

Key Research Developments

- Controlled Polymerization Techniques: Advances in techniques, such as living polymerization, have enabled precise control over the degree of polymerization, resulting in polymers with tailored properties and applications.

- Biopolymer Innovations: Researchers are exploring new methods to enhance the degree of polymerization in biopolymers, improving their mechanical strength and durability for various uses, from packaging to medical devices.

Common Misconceptions About Degree of Polymerization

Despite its significance, there are several common misconceptions surrounding the degree of polymerization, leading to misunderstandings about its impact on polymer properties and applications. Addressing these misconceptions is crucial for advancing knowledge and innovation in polymer science.

Clarifying Misunderstandings

- Higher Degree of Polymerization Always Equals Better Properties: While a higher degree of polymerization can enhance certain properties, it may not always be desirable, as it can lead to increased brittleness and processing challenges.

- All Polymers Have the Same Degree of Polymerization: Different polymers, whether natural or synthetic, can have varying degrees of polymerization, resulting in diverse properties and applications.

Frequently Asked Questions

What is the degree of polymerization?

The degree of polymerization refers to the number of monomer units in a polymer chain, influencing the polymer's molecular weight and properties. It plays a crucial role in determining the material's strength, elasticity, and thermal stability.

How does degree of polymerization affect polymer properties?

The degree of polymerization impacts various properties, such as mechanical strength, thermal stability, and solubility. Higher degrees typically result in stronger, more durable materials with improved thermal resistance.

What factors influence the degree of polymerization?

Several factors can affect the degree of polymerization, including monomer concentration, reaction temperature, and the presence of catalysts. Understanding these influences is crucial for optimizing polymer synthesis.

Why is it important to measure the degree of polymerization?

Measuring the degree of polymerization is essential for characterizing polymers and optimizing their properties for specific applications. Accurate measurement enables the development of materials with tailored characteristics and enhanced performance.

How is the degree of polymerization measured?

Several techniques can be used to measure the degree of polymerization, including viscometry, gel permeation chromatography (GPC), and nuclear magnetic resonance (NMR) spectroscopy. Each method offers unique advantages and limitations.

What is the relationship between degree of polymerization and molecular weight?

The degree of polymerization directly determines the molecular weight of a polymer, as it indicates the number of monomer units in a chain. This relationship is crucial for understanding the polymer's properties and behavior.

Conclusion

Understanding what is the degree of polymerization is essential for anyone interested in the science of polymers, as it plays a pivotal role in determining their properties and applications. By exploring the factors that influence the degree of polymerization, as well as the techniques for measuring it, we can better appreciate the complexity and versatility of these remarkable materials. Whether you're a researcher, engineer, or simply curious about polymers, grasping the concept of the degree of polymerization opens the door to a deeper understanding of the materials that shape our world.

Article Recommendations